ORLIMEX have obtained the first ever construction-technical certificate for the sale of composite materials from basalt fibres

ORLIMEX UK Ltd in 2016 expanded its business activities in the construction industry and formed a new division Orlitech to supply composite or FRP (Fibre Reinforced Polymer) materials in the UK – as a substitute for traditional steel reinforcement. Orlitech offers two types of composite materials to its business partners. These are basalt fibre materials (BFRP) and fibreglass fibre (GFRP) – these materials are a proven replacement for steel reinforcement in the concrete construction.

ORLIMEX is the exclusive representative of GALEN designated for the United Kingdom, Ireland, Netherlands, Czech Republic, Slovakia and Poland. GALEN is a World producer of composite materials and one of the first producers of composite basalt materials and glass fibre materials. Supplying business partners in the UK, USA, Europe, UAE and Australia.

to download here“ href=“https://drive.google.com/file/d/1pCLQhJgcFoCWb_3QIvxAlCD5FbkTXVGp/view“ target=“_blank“ rel=“noopener noreferrer“>Complete information to download here

BASALT

Basalt is a rock of volcanic origin and it forms about 30% of the Earth’s crust. It is an extremely durable and hard material of a fine-grained structure. It is resistant to abrasion and

chemicals. Thanks to these properties, basalt began to be used to produce modern composite materials.

Main advantages of basalt:

- high tensile strength – basalt fibre is close to carbon fibre strength (basalt is 3 times stronger than steel, but 6 times lighter)

- thermal conductivity – basalt has a low thermal conductivity (10 times less than steel), its use increases the thermal efficiency of building walls by up to 35%

- anticorrosion properties

- dielectric

- resistance in alkaline and chemical environments – long working life

- bond with concrete – bars covered with silica sand

Basalt and composites

A composite is any material that consists of at least two major components with markedly different physical properties. Our composite (FRP) reinforcement is made from a fibre reinforcement and composite binder. The most common is a composite of organic polymer resin and basalt or glass fibres.

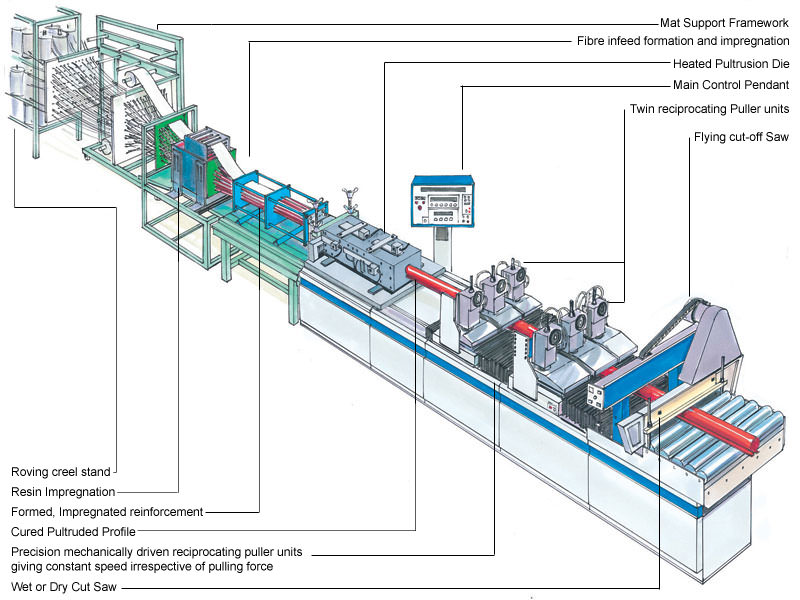

PULTRUSION – Production technology

The word “PULTRUSION” is a process of continuous production of reinforcement of various shapes and lengths by pulling hence pultrusion. The inlet material is a mixture of liquid resin and fibre reinforcement. The process involves pulling the material through a heated steel mould, sometimes filled with silica sand to increase the bond strength with the concrete and cutting to the desired length.